For more than two decades, Kitchell and Phoenix Children’s have shared a single purpose: to build spaces that heal, inspire, and advance pediatric care for generations to come. What began as a bold tower expansion has evolved into a systemwide journey — more than 26 projects, each crafted through collaboration, foresight, and an unwavering belief that every child deserves the very best environment for healing.

1. Building the Flagship: The Tower That Transformed Care

It began with a vision — a hospital that could rise to meet the growing needs of Arizona’s children. In 2011, that vision took shape in the form of a striking 11-story, 760,000-square-foot tower that forever changed the skyline of pediatric care in the Valley.

Inside, 168 new beds, 12 operating rooms, and a bustling outpatient clinic came to life — each space designed to support the extraordinary work happening within. Delivered ahead of schedule and under budget, the tower became more than a building; it became the heartbeat of a growing healthcare system.

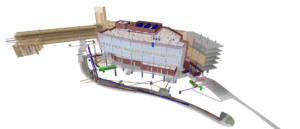

Over the years, Kitchell returned again and again — expanding the Heart Clinic, building new operating rooms, and transforming entire floors into state-of-the-art environments. The 5th floor’s evolution into a modern CVICU brought advanced technology and serenity together, while the use of BIM technology ensured that every pipe, wire, and system worked in concert. Each improvement told a story of continuity — of a partner invested not just in construction, but in care itself.

2. Expanding Emergency Services: Building Hope, Minute by Minute

Few places demand more precision than an emergency department — and few require more compassion. In 2017, Phoenix Children’s once again turned to Kitchell to expand its emergency and trauma care capacity.

The West Pavilion project added 119,000 square feet of new space and renovated 31,000 more — but its true impact was measured in moments saved and lives touched. Behind the scenes, the work was surgical in its own right. Crews coordinated overnight tie-ins, mapped every phase, and built quietly alongside a fully functioning emergency department to ensure that care never stopped, not even for a minute.

When the doors opened, they revealed more than new rooms and labs. They revealed possibility — a modern Level I trauma center, a hematology–oncology clinic, an infusion suite, and a clinical lab all working in harmony to serve the most vulnerable patients, day and night.

3. Advancing Neonatal Care: A Sanctuary in the Sky

High above the city, the 11th floor of the Phoenix Children’s tower became something extraordinary: a haven for the tiniest patients. The new Level IV NICU, completed in 2024, introduced 48 private rooms, a dedicated neuro-NICU, therapy spaces, and family lounges designed to bring comfort and calm to families in crisis.

Constructing directly beneath an active helipad demanded quiet heroics — advanced acoustical measures, rigorous ICRA protocols, and even a crane lift through a temporary window to keep patients safe. Every detail was deliberate. Every sound, surface, and light was considered.

Here, technology meets tenderness. Every monitor hums softly in rhythm with a heartbeat. Every space reminds families that healing is possible — and that Arizona’s only AAP-designated Level IV NICU stands ready to protect the state’s youngest lives.

4. Expanding Care Across the West Valley: Meeting Families Where They Are

Once, families in the West Valley faced long drives to reach specialized care. Today, thanks to Phoenix Children’s and Kitchell, they find world-class treatment close to home.

The Southwest Valley Center — first opened in 2013 and expanded through 2024 — reflects a region’s transformation. Its 35,000-square-foot emergency department now serves more than 40,000 children every year, while a 71,000-square-foot multispecialty clinic connects families to more than 20 subspecialties under one roof.

Behind every square foot lies a story of growth: of neighborhoods once defined by citrus groves now defined by opportunity, and of a hospital system determined to meet families where they live — ensuring that no child’s care is ever out of reach.

5. Delivering a New Pediatric Destination: Arrowhead Campus Rises

In Glendale, an abandoned citrus orchard became the soil for something transformative — the Arrowhead Campus, one of the Valley’s most forward-looking pediatric destinations.

Completed between 2023 and 2024, the campus includes a 180,000-square-foot hospital, a 45,000-square-foot multispecialty clinic, and a 12,000-square-foot central utility plant — all woven into the fabric of the community. The path wasn’t without challenges: shifting municipal requirements, evolving city projects, and a central plant located just 79 feet from nearby homes. Yet through collaboration with HKS, TRUEFORM, and the City of Glendale, Kitchell kept the project moving — and delivered exactly what was promised. Hear from members of the Kitchell project team as they share reflections from the final stages of construction:

What emerged was more than a hospital. The once-silent orchard became a place of serenity and care, framed by a healing garden where light dances through a curving privacy wall. The design language of Phoenix Children’s — bright, welcoming, hopeful — is etched into every detail, inviting families to rest, breathe, and heal. Hear TRUEFORM architect Todd Briggs offer his perspective on how this space came to life:

6. Opening Space for Growth: Building the Future Behind the Scenes

Sometimes, the most transformative projects are the quiet ones — the ones that clear the way for what’s next.

On the Thomas Campus, a 94,000-square-foot office building did exactly that. By relocating nonclinical teams into a modern, light-filled workspace, Phoenix Children’s unlocked the potential to add nearly 100 new inpatient beds and expand family spaces in the main tower.

Even in a volatile market, the project held firm — completing within 0.1% of the original GMP and ahead of expectations. The building’s distinctive angled “gills,” refined through more than ten engineering iterations, carry forward the campus’s architectural rhythm while introducing energy efficiency and sophistication.

And through early collaboration with city partners, Kitchell eliminated a costly sewer reroute and avoided a month-long delay — proof that foresight and partnership remain as vital as concrete and steel.

Strengthening Care for Every Child

From the heart of downtown Phoenix to the farthest reaches of the West Valley, the partnership between Phoenix Children’s and Kitchell has built far more than buildings. Together, they’ve created environments of comfort, courage, and care — each designed around the needs of children and families.

This is a legacy still in motion. A story still unfolding. And as Phoenix Children’s continues to grow, Kitchell remains at its side — building the future of pediatric care, one meaningful story at a time.